Inline Measurement and Control System for Offset Printing

The use of the LithoFlash® Inline system sustainably improves the productivity of your existing or new printing machines. With a low investment volume, the system achieves significant savings in a short time. Reduced setup times increase job throughput, while high waste savings directly lower substrate costs. The use of the measurement and control system also ensures highest quality during production.

Quality Assurance at the Highest Level

The LithoFlash® Inline system from Lithec revolutionizes quality assurance in the printing process. It measures and controls the densities of process and special colors in real-time, leading to a drastic reduction in setup times and waste. This significantly lowers substrate costs and boosts the productivity of your printing machine. Thanks to easy installation and retrofitting options, LithoFlash® Inline is suitable for printing machines of all manufacturers and formats. The combination of inline measurement and density control not only enables professional quality assurance, but also a sustainable increase in your competitiveness. Benefit from state-of-the-art measurement technology that optimizes your printing processes and delivers consistent results.

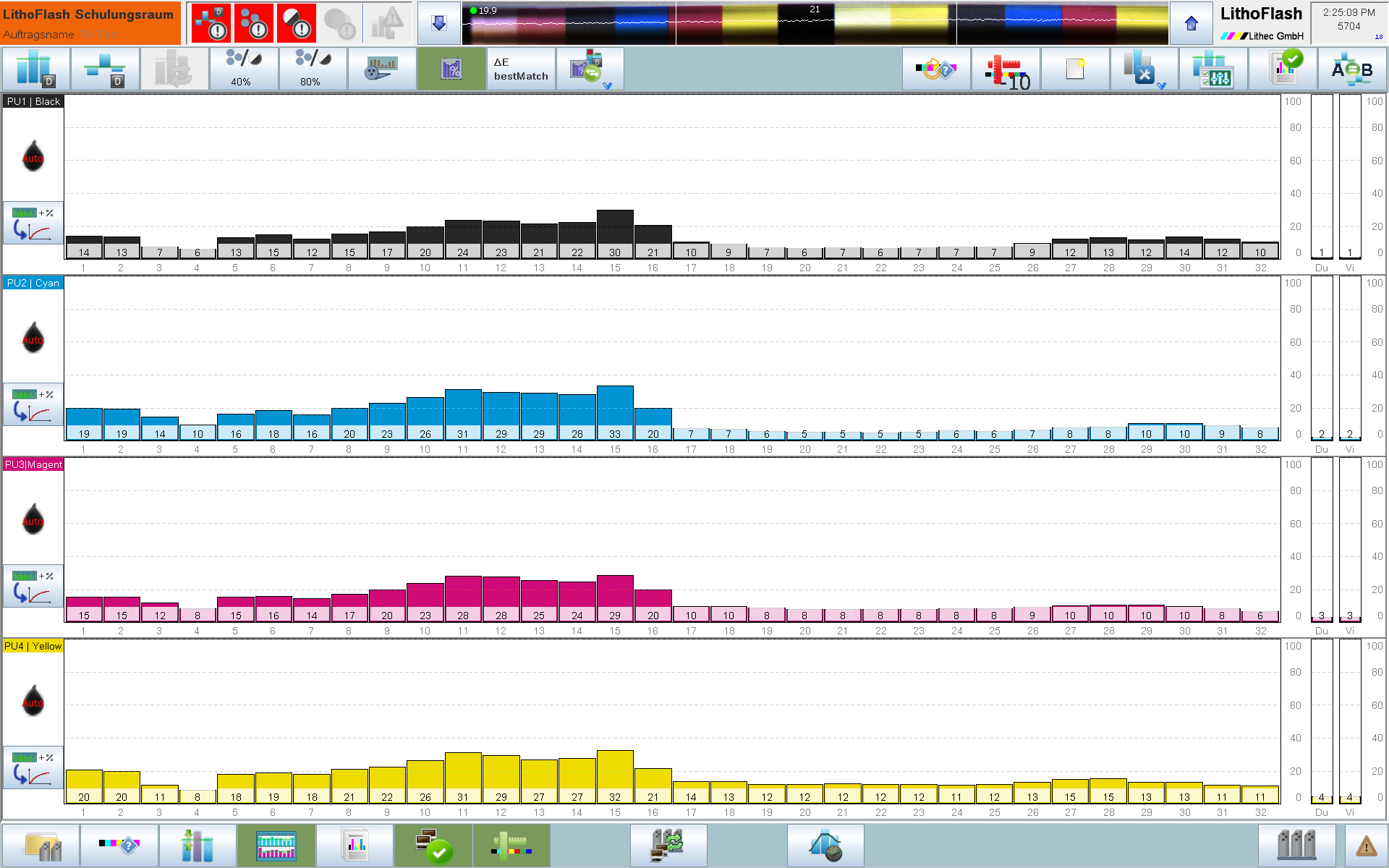

Precision and User-Friendliness

LithoFlash® Inline offers dynamic control of printing processes and ensures consistent print quality for every job. The system monitors and controls tone gain, print contrast, and trapping, resulting in precise color reproductions. The user-friendly interface allows for intuitive operation and quick analysis of measurement results. With energy-efficient LED flash lighting and a low-maintenance design, LithoFlash® Inline is particularly reliable and durable. Experience a new dimension of print quality with a system designed for the highest demands in offset printing.

LithoFlash® Inline for Sustainable Printing Processes

With LithoFlash® Inline, you are investing in a future-proof tool that optimizes your printing processes and enables rapid return on investment. With low investment costs, the system brings significant savings and a high increase in efficiency in a short period. The innovative sensors, combined with effective dust protection, ensure lasting precision. LithoFlash® Inline supports standardization according to PSO or individual in-house standards, guaranteeing consistent printing results and satisfied customers. With LithoFlash® Inline, you secure sustainable advantages in the printing process.

Expand Your Potential with Our Other Products

Sensor Technology and Measurement:

Type:

Optic

Measurement:

Light Source:

Measurement Range:

Sheet/Web Speed:

Sheet Width:

Components:

Inline Traverse with Mounting

PC with Touchscreen

Control Unit

Incremental Encoder and Components

Machine Integration:

Colorbars:

Standard:

Custom:

Minimum Height:

Download manuals, data sheets, or contact our support team for personalized assistance.