Die cutter control system for misprinted sheets without special markers

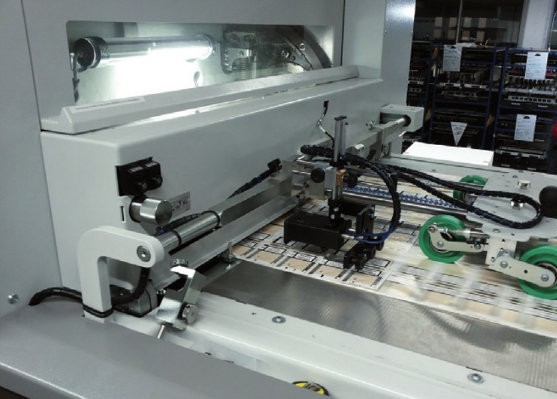

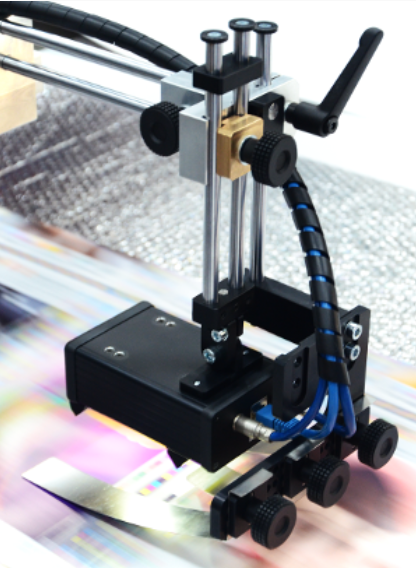

LithoCheck determines all faulty sheets in the die cutter and stops for release at the feed table. An automatic lock out can be started. Measurement is performed using an RGB camera sensor. For measurement, printed motifs or structures are suitable as markers.

Precision in Die-Cutting Control

LithoCheck is an advanced control system that enables reliable detection of faulty sheets without the need for special marks. The system precisely measures printed motifs using an RGB sensor and stops faulty sheets for removal. Alternatively, a diversion is activated to maintain the production flow. This allows LithoCheck to help ensure quality assurance at the highest level.

Quality Monitoring for Printing Machines

With LithoCheck, printing companies and converters can automate their quality control. The compact color sensor with LED lighting detects even the smallest geometric deviations and enables quick error analysis in less than 10 milliseconds. The automatic storage of error logs and the option for touch control ensure intuitive handling and easy integration into existing systems.

Flexible and Versatile Application

LithoCheck adapts flexibly to various machines and production environments. Whether in die-cutting machines, collating machines, or sorting systems, the system impresses with its universal applicability and easy integration. Options such as PDF logging or a signal light for visual notifications complete the system, making it an ideal tool for modern production control.

Sensor Technology and Measurement:

Measuring System:

Evaluation Time:

Evaluation Area:

Precision:

Error Logging:

Applications:

Sheet Width:

Components:

Compact color sensor (80 x 65 x 120 mm) with X/Y position adjustment

Integrated PC with TFT touch monitor

LithoCheck software

Download manuals, data sheets, or contact our support team for personalized assistance.