Measuring, Controlling, Inspecting

As a world-leading company in print press optimization, we offer comprehensive solutions in all areas.

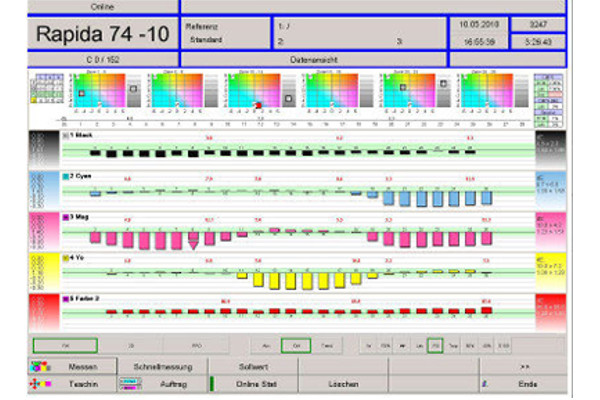

Inline Measuring and Control System for Offset Printing

The use of the LithoFlash® Inline system sustainably improves the productivity of your existing or new printing machines. With a low investment volume, the system quickly achieves significant cost savings. Reduced setup times increase job throughput. The high reduction in waste directly lowers material costs. Additionally, the use of the measuring and control system ensures consistent production quality.

LithoScan SIP available in various versions

Powerful system for complete RGB image control on printing machines outside the press. Our new SIP system combines spectral measurements, inspection, and PDF verification.

Up to 50% waste reduction through the fastest setup

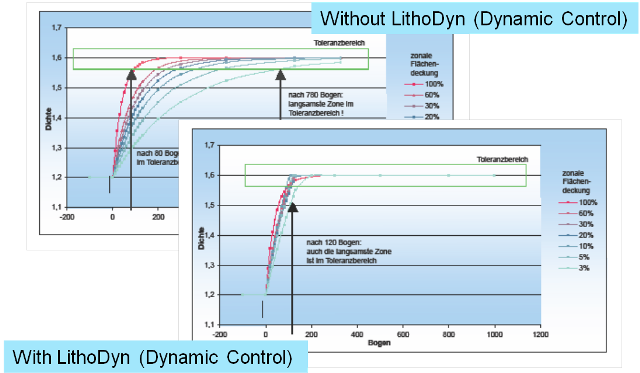

All conventional offset printing units require between 70 and 800 sheets, depending on the ink coverage, to reach stable coloring.

Optimal Control According to PSO Standards - Software Option for LithoScan

The software controls the coloration of printing machines so that the specifications of the Process Standard Offset (PSO) are quickly and reliably achieved.

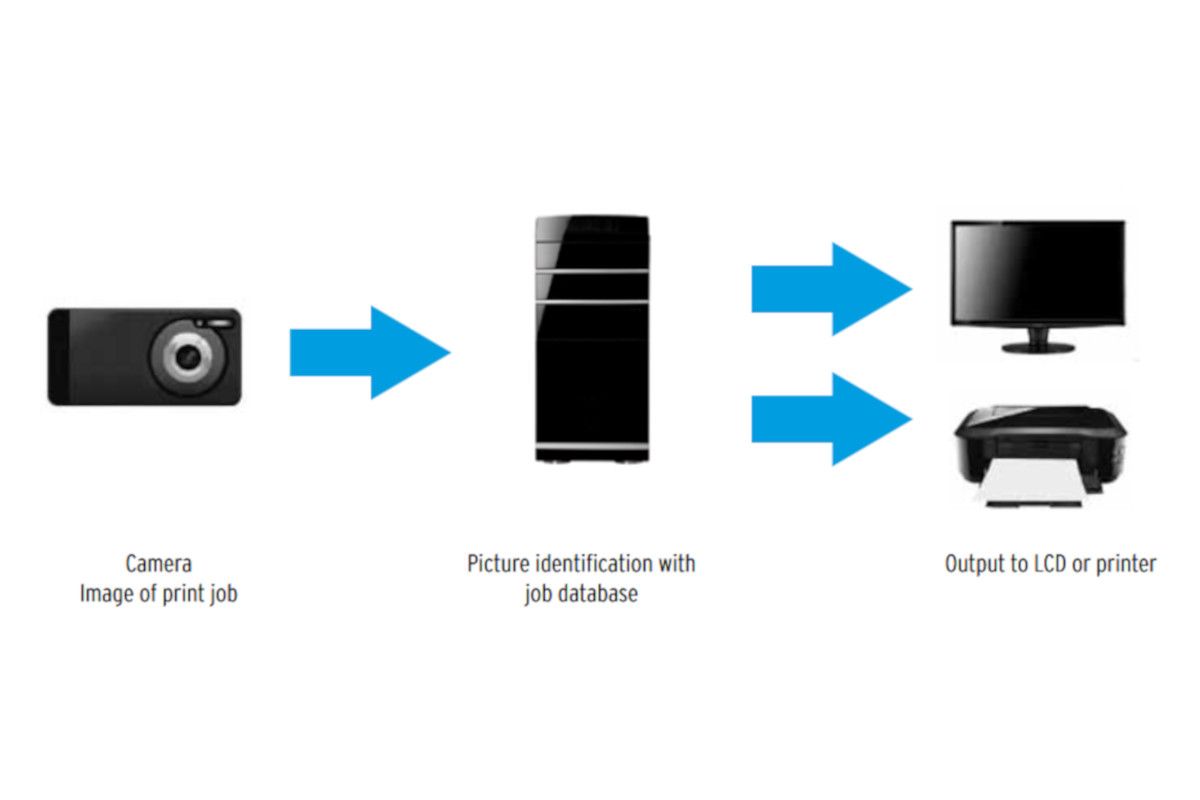

Die Cutting Control

LithoCheck reliably detects all defective sheets entering the die cutter and stops them for removal on the feed table. Alternatively, a rejection system can be triggered. Measurement is carried out using an RGB sensor. Printed motifs or structures are sufficient; special marks are not required.