Optimal Quality Control and Error Detection with LithoScan SI

Discover how the LithoScan SI system maximizes print quality, detects errors in real time, and supports various applications—for precise and efficient printing processes.

Precise Error Detection in Real Time

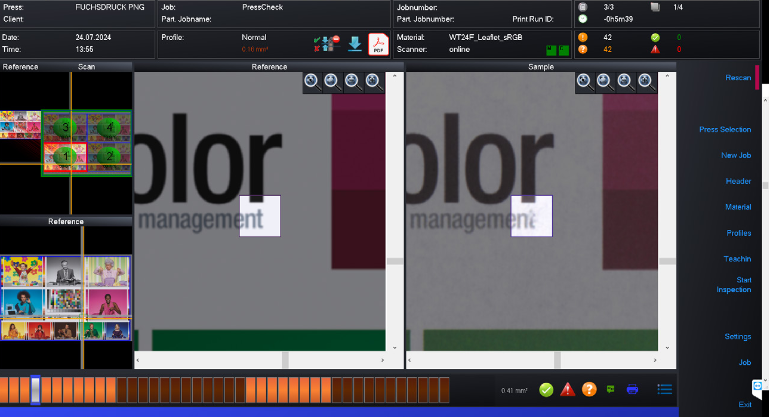

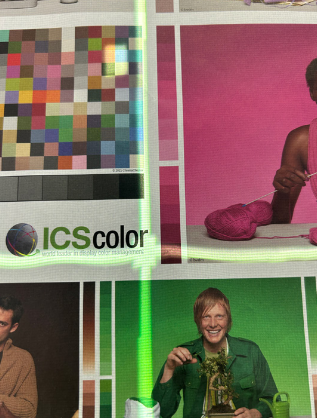

The LithoScan SI system enables immediate sheet-to-sheet comparison and error classification. Thanks to the integrated, maintenance-free LED lighting and the RGB line camera, even the smallest image deviations such as scratches, spots, and incorrectly used fonts can be detected. The real-time adjustment of error thresholds ensures the highest precision and reliability in print inspection. This system optimizes your quality control and saves valuable time.

Versatile Application Possibilities

LithoScan SI is suitable for various printing applications, including the highly demanding pharmaceutical sector. With features like PDF and image inspection at the press, as well as optional laser error localization, the system is highly versatile. Different configurations for diverse requirements make LithoScan SI the ideal solution for modern printing processes.

Efficient Quality Control and Documentation

The system is characterized by comprehensive logging: error and history logs are automatically created and are easy to manage via the touchscreen. Thanks to the PDF comparison function and quick error review directly on the monitor, operators can address errors immediately, significantly improving quality assurance.

LithoScan is available in the following versions

Sensor Technology and Measurement:

Type:

Optics:

Measurement:

Measurement Range:

Web/Sheet Speed:

Sheet Width:

Components:

RGB line camera with lighting

PC with touchscreen

Industrial PC with control unit

Image comparison software

Speed and Performance:

Scan Time:

Evaluation Time:

Formats:

Download manuals, data sheets, or contact our support team for personalized assistance.